E-Atık Geri Dönüşümü

Demcore’da, tehlikeli maddelerin çevreyi kirletmesini önlemek ve altın, gümüş ve bakır gibi değerli metalleri geri kazanmak için kapsamlı e-atık geri dönüşüm çözümleri sunuyoruz. Tasarlayıp, kurduğumuz tesislerin prosesleri toplama, ayırma, sökme, parçalama ve malzeme geri kazanımını içerir. Ayrıca, kurduğumuz tesisler elektronik atıkların sorumlu bir şekilde ele alınmasını sağlar ve sürdürülebilirliği teşvik eder.

Bakır ve Alüminyum Geri Dönüşümü

Demcore, bakır ve alüminyum geri dönüşümünde etkin bir rol alarak, kaynakları korur ve çevresel etkiyi azaltır. Hurda metalleri toplayan, ayıran, parçalayan ve rafine eden tesisler tasarlar ve sürdürülebilir uygulamaları ve döngüsel ekonomiyi destekleyen yüksek saflıkta geri dönüştürülmüş malzemeler üretilmesini sağlar.

Auto Spent Catalyst Recycling

We recycle automotive catalytic converters to recover precious metals like platinum, palladium, and rhodium. This process reduces the need for mining, lowers emissions, and promotes resource efficiency, contributing to environmental sustainability.

Li-On Battery Recycling

Demcore’s Li-On battery recycling process recovers valuable metals like lithium, cobalt, and nickel, reducing environmental risks and conserving resources. By reintroducing these materials into new production cycles, we support a sustainable future and reduce reliance on raw material extraction.

Wire Technology

Wire Technology

Demcore is a research and development company that produces high-performance copper and aluminum wire products and develops machinery and equipment. Our solutions include material innovations, advanced production processes, and strict quality control stages. Our focus is on improving system efficiency and promoting sustainability through eco-friendly materials and recycling practices.

Cable Technology

Cable Technology

We develop machinery and equipment used in the production of cables, which consist of multiple wires twisted together and covered with an insulating outer material. Our work includes material innovations, precise manufacturing processes, and rigorous testing. Our cable technologies ensure reliable power and data transmission, reduce energy losses, and support sustainability through eco-friendly production and recycling.

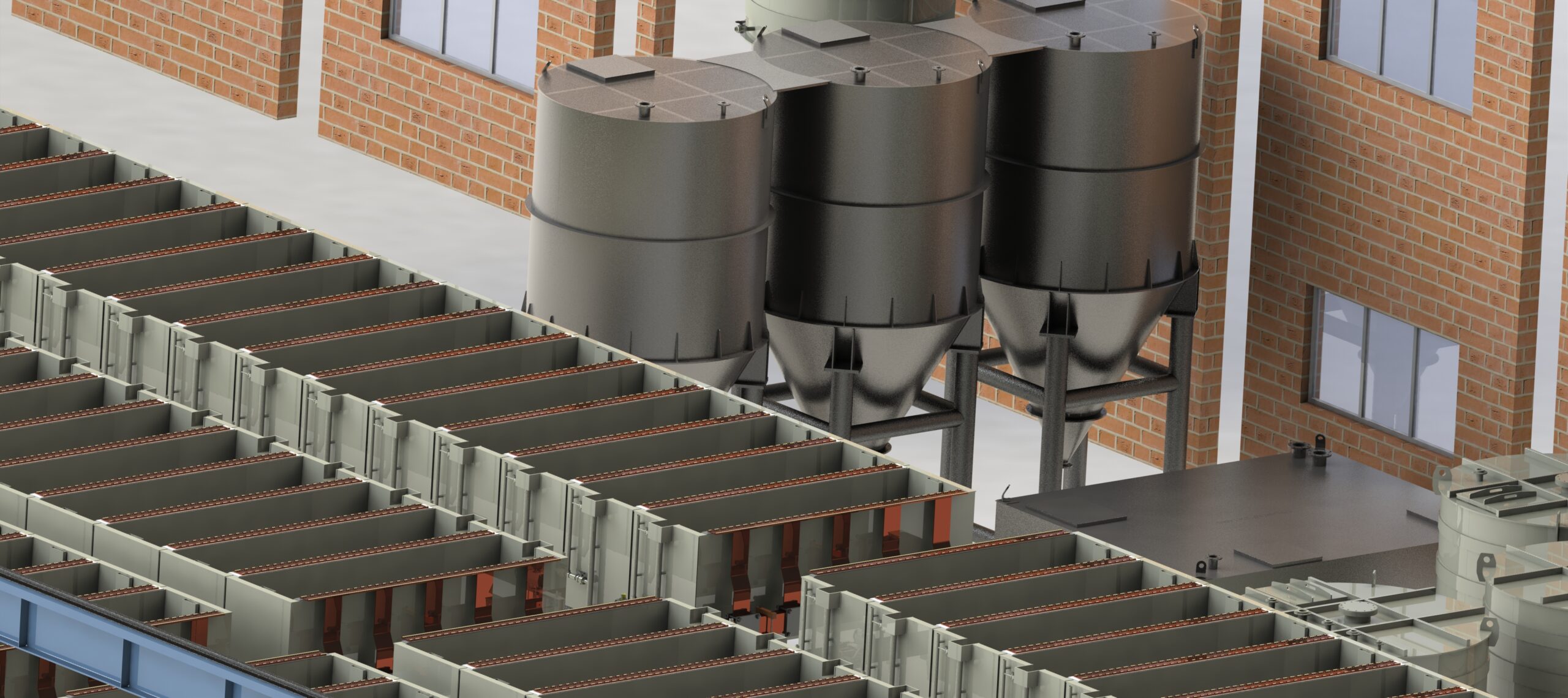

TBRC (Top Blown Rotary Converter)

TRF Furnace (Tilting Rotary Furnace)

Thomas Furnace

Induction Furnace

Wire Equipment

Cable Equipment